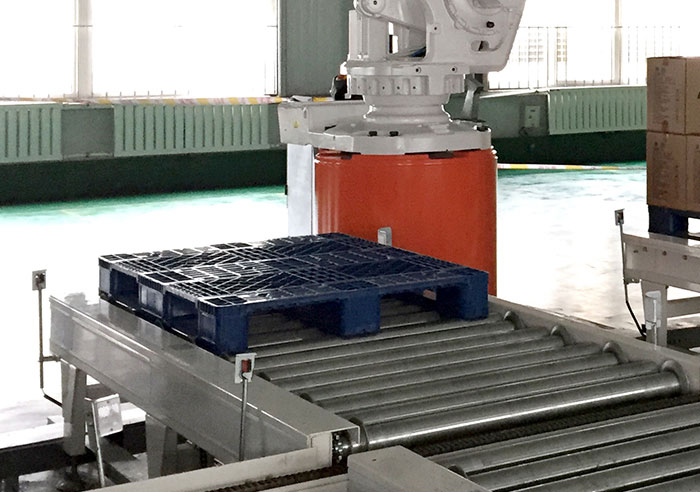

Palletizer

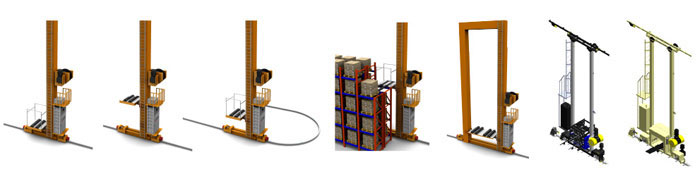

Stereoscopic warehouse shelf

The steel structure rack is the main equipment for storing goods in the high-level rack storage area, which requires sufficient strength and rigidity and overall stability, the size must be of high precision and the seismic demand must be met. The system's shelves adopt adjustable crossbeam, which consists of rack pieces, loading beams and reinforced support rods, plug connection, the height is adjustable, the adjustment spacing is 75mm, and the position height can be adjusted if necessary. It is convenient to transport and install, and the assembled racks mainly meet the requirement of the long-term automatic operation of stereoscopic warehouse equipments.

Structural features

The shelves are mainly composed of shelf plate (upright), crossbar/bracket, top crossbar, and stiffener.

The main components of the racks are thin-walled steel, and the shelves are manufactured by fully automatic rolling mills with high degrees of automation, high precision products, strong development, non-pollution and reliable safety.

The surface treatment adopts electrostatic powder spraying, and after surface spraying treatment, the finished goods rack has beautiful appearance and strong resistance corrosiveness.

The beam is positioned on the upright of the rack plate, so as to prevents the beam from withstanding the heavy impact, which may make the fracture of the hanging disc cause the beam and the goods to fall.

CONVEYING EQUIPMENT

The conveying equipment includes chain conveyor, roller conveyor, transfer machine, hoister, AGV, pallet truck working machine, RGV, etc., it is very common in the field of production logistics, such as workshop transmission line, on-line packaging line, car assembly line, etc.

In the automated warehouse system, the conveying system is a channel and bridge that connects the production site, the operating zone and the storage area, with a high degree of automation, high efficiency of continuous operation, low maintenance costs, convenient and efficient and so on.

AGV

Automated Guided Vehicle (AGV) refers that the transport is equipped with electromagnetic or optical automatic guide device and could drive along the designated guide track as well as is featured by the safety protection and various delivery functions. When it is used into the industry as a moving van, no driver is needed and rechargeable battery could supply power for it. Its routes and actions are generally controlled by the computer; the electromagnetic path attached on the floor is adopted to set up its route, and AGV shall act or move according to the signals sent by the electromagnetic path.

Pallets